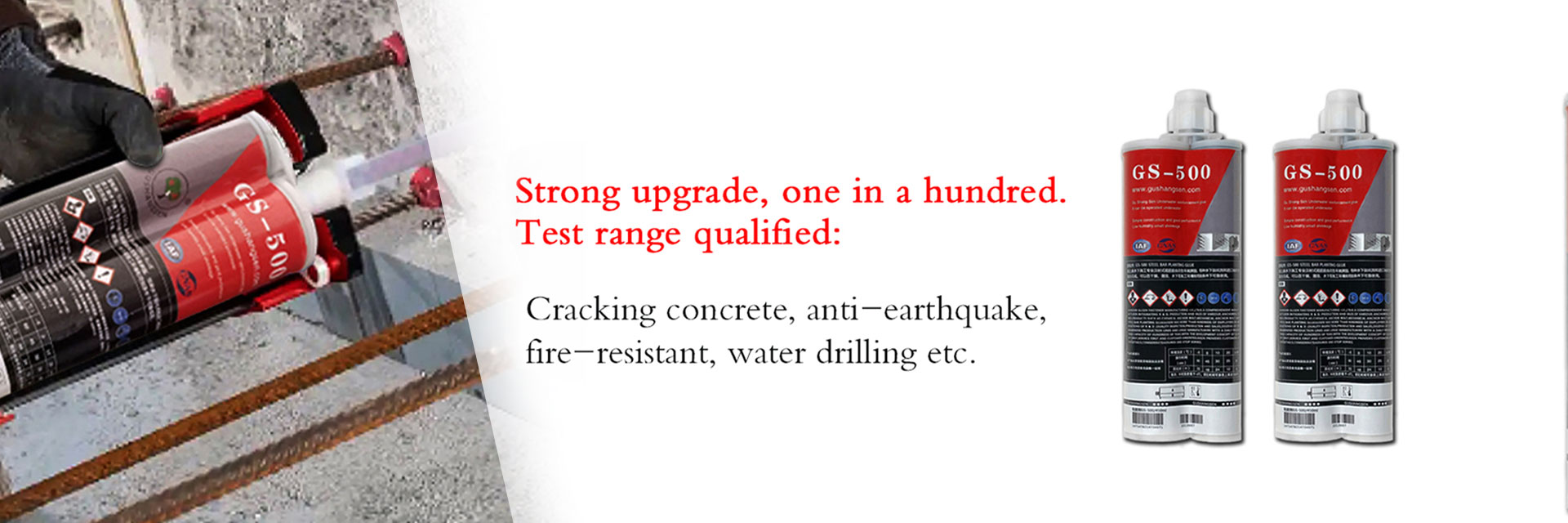

Silicone Sealant, Injection Epoxy Binder, Gs-500 50 Years Warranty.

Epoxy injection is an economical method of repairing non-moving cracks in concrete walls, slabs, columns , marble etc.

The strongest metal-to-metal connections are formed with epoxy adhesives. They are made up of two parts: glue and hardener. These factors work together to form a strong, long-lasting bond between metal kinds or between metal and concrete surfaces.

Before working on injection, it is necessary to check the conditions of the cracked areas. If the site of cracking has not been determined and remedied, the concrete will lead to crack again.

Firstly, make the crack clean and the surface that surrounding it make sure paste-over can bond to sound concrete. At a minimum, the surface to receive paste-over should be brushed with a wire brush. Meanwhile,in order to make sure the paste-over to bond properly, such as oil, grease or other surface contaminant must be cleaned . During cleaning, pay attention not to impact any debris into the crack . taking clean, oil-free compressed air, blow out the crack to remove any dust, debris or standing water.

At the time of injection, the crack is dry is best. If water is continually seeping from the crack, the flow must be stopped in order for epoxy injection to yield a suitable repair. Other materials such as polyurethane resins may be required to repair an actively leaking crack.

If a coating, sealant or paint has been applied to the concrete, it must be removed before placing the paste-over epoxy. Under the pressure of injection, these materials may lift and cause a leak. If the surface coating is covering the crack, it may be necessary to route out the opening of the crack in a “V” shape using a grinder in order to get past the surface contamination.

GUSEN epoxy adhesive is professional for infrastructure, civil engineering projects and heavy construction. Its high performance and steady feature fit wide climate applications. Special formula for tropical, winter season and non-sag bonding demand. Flexible use for longer curing time and various market.

When start working, the glue just run out, due to not mix together thoroughly, can not work in around 20 minutes, otherwise solidify problem happen.

In 30minutes, glue will solidify at the mouth of the tube. Need clean the mouth of tube with acetone to continue.

Remark: the red screw rod in the tube is for mix glue and cure agent, Do not drop it.

Steel glue application in different projects

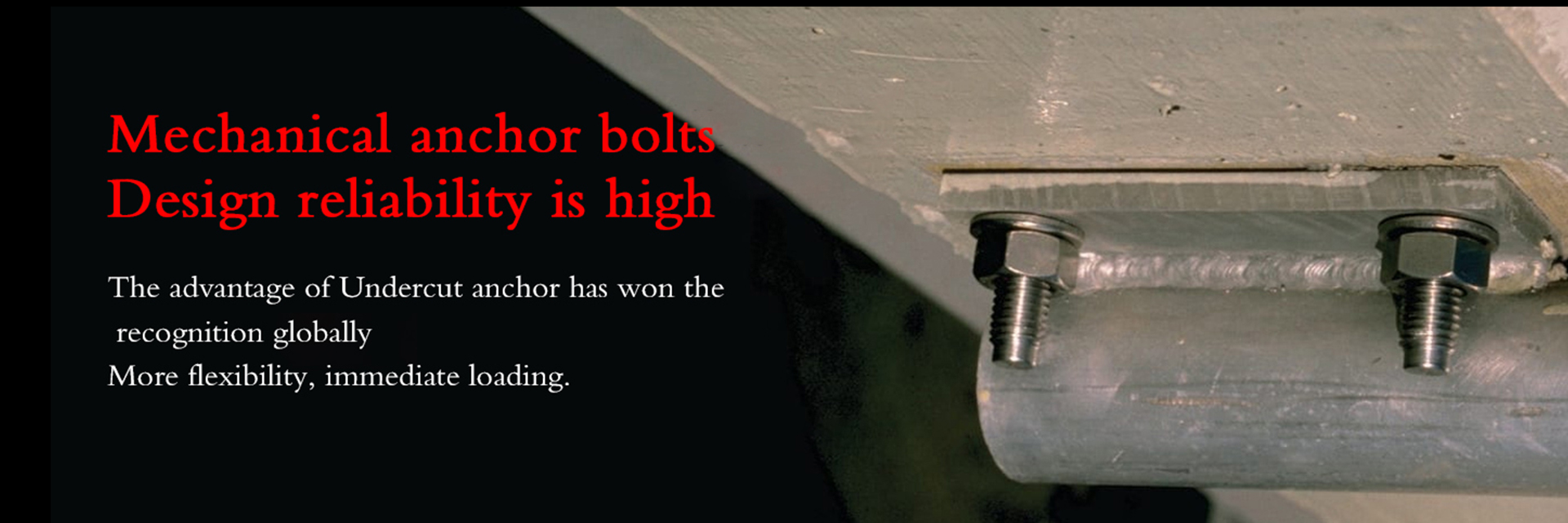

Steel connected fix rail

Fasten screws anchor fixed

Strong bond

Anti-corrosion

Open water installation

A Grade

Injection steel glue

A-epoxy adhesive

Static mixing tube

environment friendl